Last report for this month, for your reading pleasure 🙂

Kanonkop maintenance 20191026

Meetup at gate (at tar road) +_ 09:00.

Drove up.

VHF Repeater

Connected a test repeater direct to duplexer (By passed all filters and pre amp except duplexer). Repeater was set at 0.22uV to open.

Received ZS1GVW with lots of rain on signal (ZS1GVW running 20w)

Received ZS1GVW clear (ZS1GVW running 60w)

Did receive some interference on RX.

Tested if CTCSS was a good enough filter (Confirmed).

Local RF noise suspected to be around 0.3uV

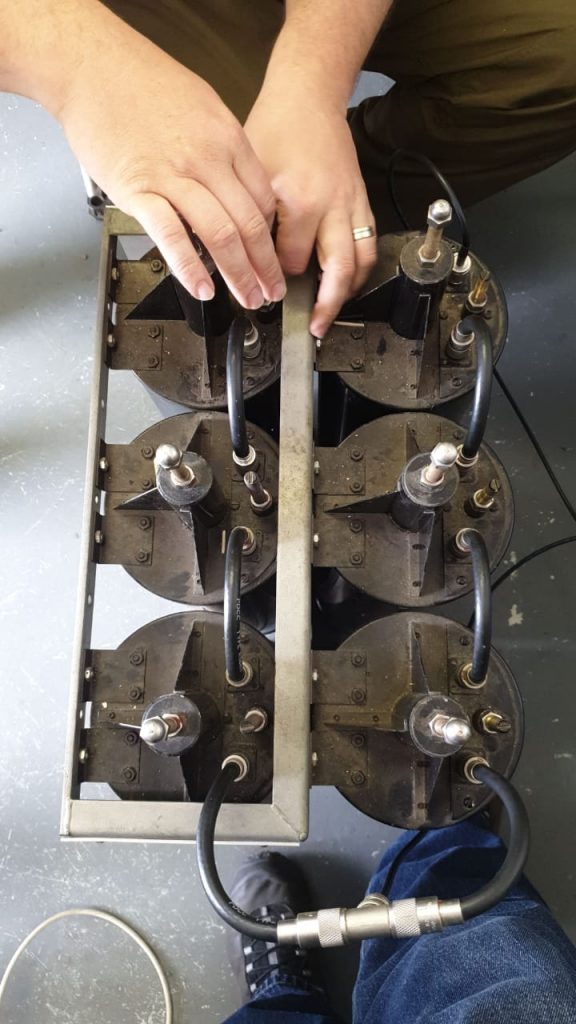

Removed 1 can from Celwave cavity set and retuned for 145.750 (-0.58dB insertion loss)

Replaced VHF Engineering Bandpass filter with Celwave cavity (Insertion loss moved from -2.7dB to -.58 dB)

Bypassed one of the two cavity bandpass filters in RX side (left -0.97dB)

Reconnected the installed PYE repeater.

Power after duplexer up by 60% +_ 15W output now.

UHF repeater:

Checked all cables.

Fixed N-male connector on RG214 between duplexer and repeater in RX path)

Retuned duplexer (434.625 -0.79 dB / 433.025 -1.38 dB / 102 dB isolation)

Placed duplexer back.

Measured power and SWR:

Repeater output 30W SWR 1

After circulator 27W SWR 1

After duplexer 22W SWR 1 (With dummy load)

After duplexer 22W SWR 1.4 (With antenna)

Tested sensitivity direct on repeater (3.5uV)

Investigated repeater. In process of investigation sensitivity went down to 0.55uV, but lots of rain) Could not measure 12db sinad, but suspect it to be around 5uV (the by ear test).

Sensitivity was at 0.55uV at end.

Finshed around 14:30 and drove down.

Summary

More thinking will need to be done about Heliax state.

VHF Repeater

TX side: improved output by swapping out band pass filters (2.1 dB improvement, output now 15W)

RX side: removed 2 cavity bandpass filters (improved RX by 3.63 dB)

UHF Repeater

TX side: improved by 0.83 dB

RX side: improved by 4.7 dB

UHF repeater is not healthy.

TODO:

Investigate Antenna options VHF

Investigate why 1.4 SWR on UHF

Decide on Feeder

Think about linking

Service UHF Repeater

Repeater Status Report 20191022

Kanonkop maintenance 20191019

Meetup at gate (at tar road) +_ 09:00.

Drove up.

Measured Power and SWRs

Batteries 13.3V and 13.2V

Power Supply Unit right 26.64V

Power Supply left (DC to DC) 13.7V

Power Supply RHS against rack (DC to DC) 13.8V (Negative grounded on rack)

Between Duplexer and Heliax 10W SWR 1.4

Between T4002 and circulator 30W SWR 2

Between Circulator and Band Reject Filter 16W SWR 1.7

Between Band Reject Filer and Duplexer 13W SWR 1.4

Tested Heliax and Antenna

Used hand radio as source

Bottom 6W SWR 1.4

Removed antenna and replaced with dummyload

Bottom 6W SWR 1.4

Top 5W SWR 1

Reconnected antenna

Top 5W SWR 1

The 2 stage circulator was retuned to correct SWR problem (145.750 before -1.2dB SWR 2 after tuning -0.38 dB SWR 1) The first cap in circulator is suspect.

Bandreject (Notch) filter on 146.2375 was measured and the one nut was tightend

The duplexer was measured and retuned to get a beter insertion loss on 145.150 (before -1.95db after -0.74db) (One cable in harness was found to be wrong length and was replaced)

Wideband bandpass filter was measured. This was connected between cavity bandpass filter and preamp. Moved to be between circulator and bandreject filter.

Cavity bandpass filter was retuned for beter pass band. (before -5.71dB after -4.6dB)

Tested gasfet preamp (145.150 +16 dB)

All equipment was labeled with measurements.

Repeater sensitivity measured -0.4uV

Everything reinstalled and some final measurements

Between T4002 and circulator 30W SWR 1

Between ciculator and Wideband bandpass 27W SWR 1

Between wideband bandpass and band Reject filter 12W SWR 1

Between band reject filter and duplexer 11W SWR 1

After duplexer, just under 10W

Sensitivity after duplexer 0.3uV

Tested UHF dipole antenna on side of building (good strong signal to 438.800)

Cleaned up and drove down +_ 15:30.

Summary

More thinking will need to be done about Heliax state.

TX side: losses was improved and corrected, but with the introducing of the wideband bandpass in the correct place, no power was gained.

RX side: removed wideband bandpass (2.2 dB improvement), returned cavity bandpass (1.1 dB improvement), retuned duplexer (1.2 dB improvement) Total 4.5 dB improvement

TODO:

Investigate Antenna options

Decide on Feeder

Think about linking

Retuned Wideband bandpass Filter to have less loss on 145.750 (currently -2.7db)

Move preamp before cavity BP filter. (This would just make more sense to amplify, before filter)

Remove one can from Cavity BP filter, retuned for 145.750 and replace wideband BP filter. (Will make about 1.2db more sensitive on RX and about 2dB less loss on TX)

Service UHF

Repeater Status Report 20191015

Good evening. The latest status report for your reading pleasure.

Repeater Status Report 20191008

For your reading pleasure, the latest status report here is. Enjoy it you will. 🙂

Repeater Status Report 20191001

Good afternoon!

Here’s yesterday’s report for your reading pleasure.

Repeater Status Report 20190924

All I shall say is that it was Heritage Day. 🙂

Repeater Status Report 20190917

This should have been posted last night but one of our naughty dachshunds grabbed my specs off the bedside table yesterday afternoon and chewed them to bits. Fortunately, I had an emergency pair at work.